|

Shortages of rifles in the early months of the First World War forced combatant nations to seek industrial manufacturing capacity wherever it was available. This global search resulted in a number of contracts between the belligerent nations known as the “Allies” (e.g., Great Britain, France, Russia, Belgium, etc.) and manufacturers in the United States. These contracts for the production of foreign service rifles changed the face of the American munitions industry. American firearms companies that had been sporting arms manufacturers before the war became massive military arms suppliers. Archetypal of these changes was the experience of the Remington Arms Union Metallic Cartridge Company. At the outbreak of the First World War, America was entering into an economic recession. Many American firearms manufacturers decreased production volume and discontinued firearm models that had only marginal sales. The huge and unanticipated scale of the war’s early battles, and the associ- ated wastage and loss of military materiel, rapidly exceeded all the combatants’ logistics plans and forecasts. Stockpiles and reserves were used up at an unprecedented and alarming rate, and a number of nations faced critical munitions shortages that threatened their ability to sustain combat operations. |

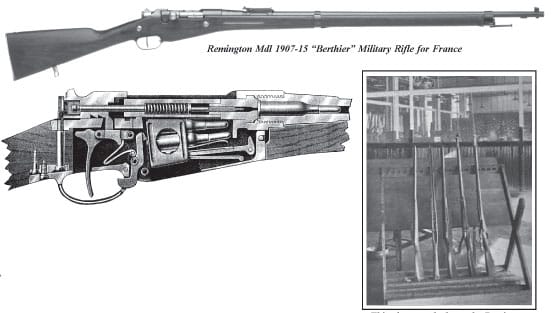

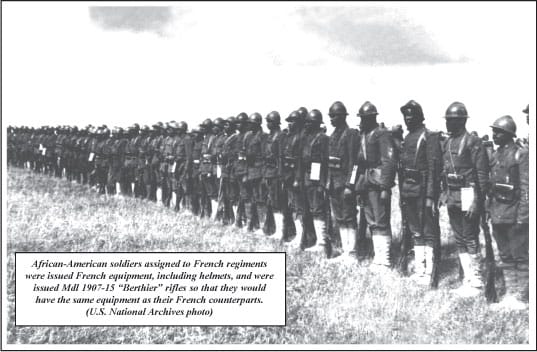

Emblematic of the shortages was the shortfall in available military rifles with which to arm infantry formations. Extraordi- nary battlefield losses created a great need for new sources of rifle production. Great Britain and Russia had the largest rifle shortfalls. The needs of Great Britain with its rapidly growing army, and Russia with its large and under-equipped army, far outstripped available supplies. France, the other major Allied nation, also needed more rifles than could be supplied domesti- cally. The Allies found available manufacturing capacity to meet their rifle requirements. American manufacturers, seeing a great potential for profit, eagerly accepted the rifle contracts. Many countries accepted contracts despite having little or no arms making experience. Remington received the majority of Allied rifle contracts, including eight that were awarded in 1914 and 1915 (endnote 1). These comprised three British contracts for a total of 1 million Enfield Pattern 1914 rifles, three Imperial Russian contracts for a total of 1.5 million Model 1891 Mosin-Nagant rifles, and two French contracts; 250,000 Mdl 1907-1915 “Berthier” rifles and 100,000 Remington Model 1914 “rolling block” rifles modified for the French Lebel cartridge. |

| Page 22 | 2nd Quarter 2012 |

|

The first rifle contract awarded to Remington was for the single shot military rifle

|

|

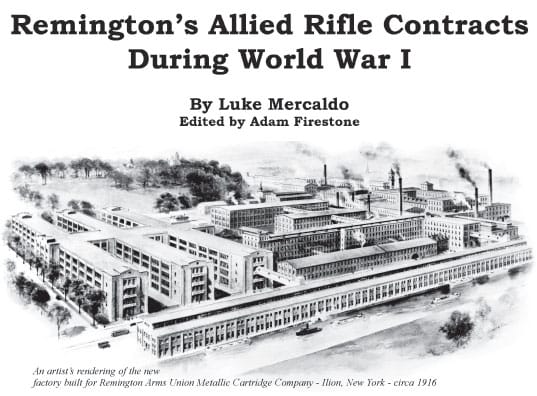

Execution of a military rifle contract is qualitatively different than market driven sporting rifle production. The contract dictates the number of rifles made and duration of the production. Agree- ments of this type often specify the manufacture of a large quantity of rifles within a specific period of time. Additionally, the technical requirements for a military rifle are different than those of a sporting rifle. Although sporting rifles made in America were of high quality, they were not subject to any external proofing or interchangeability requirements. In contrast, these were critical attributes of military rifles. This, combined with the sheer volume of production required machinery capable of making precision parts in mass. As a result, the scale of the Allied rifle orders was beyond the capability of existing factories at the start of the war. American firearms companies did not have the factory space, equipment, or the trained personnel to meet the required volume and technical specifi- cations necessary for military rifle production. Remington was no exception. Despite this, Remington began aggressively planning for military rifle production prior to any contract awards. Marcellus Hartley Dodge, the owner and Chairman of the Board of Remington, was in Germany at the beginning of the war. Realizing both the significance and scope of the unfolding war, Dodge began a massive building effort at the company gun making facility in Ilion, New York, and the ammunition making facility in Bridgeport, Connecticut. At the same time Dodge ordered new gun- making and cartridge-making machinery upon his return to America. |

Despite these measures, Remington was still unprepared for the complexities inherent to the monumental military rifle contracts that would come. Except for the first contract, all of Remington’s Allied rifle contracts suffered from extended delivery delays, which resulted in both contract modifications and corporate changes. Remington was not unique; this was an industry wide problem that was to plague virtually all of the companies involved with Allied rifle contracts.

The “rolling block” rifle production line in Ilion was already

In Ilion, Remington razed most of the antiquated armory buildings |

| Page 23 | 2nd Quarter 2012 |

The new Remington factory in Ilion began in late 1914, a direct result of receiving the large order for Pattern ‘14 rifles from Great Britain. All work was done by the James Stewart Company of New York. Note the work taking place in the late winter months with snow on the ground. This photograph is dated March 3, 1915.

|

Remington’s Ilion works was expanded by the razing of most of the older armory buildings and the addition of many new buildings. Construction began after the first British Pattern 1914 rifle contract was signed. The Ilion building complex was finally completed in mid-1916, although rifle production commenced earlier when some of the buildings were ready. The Ilion buildings were constructed in record time allowing for the new equipment and machinery installation. With the problems inherent with making guns at the same time that nearby buildings were being erected, the execution of the British Pattern 1914 rifle contract was delayed by late machinery and equipment arrivals. Additionally, Remington engineers struggled with the inexact specifications and ambiguous requirements that had been provided by the British. As a result, production engineering work had not been completed by the time production of the Pattern 1914 began. Ultimately, late rifle deliveries and a reduction in Great Britain’s rifle needs led to a renegotiation of Pattern ‘14 contracts, reducing the final number of rifles required. This was to become the norm with Remington as similar delays transpired with the Imperial Russian and French contracts. |

Construction on Remington’s Bridgeport Rifle Works was underway by March 1915. This factory was built to manufacture Imperial Russian Model 1891 Mosin-Nagant rifles. The size, and expected capacity, of the new factory gave Remington the confidence to accept another contract from the French for Mdl 1907-15 “Berthier” rifles. Additional Imperial Russian contracts for Mosin-Nagant rifles were also awarded. As had happened with the Pattern 1914 contracts, Remington was unable to meet initial contractual deadlines. The massive “million square feet under roof” rifle works in Bridgeport was built rapidly. Sections were opened for partial machinery installation in the summer of 1915, and completed in late 1915. Despite this rapid construction, delays in deliveries of rifle making machinery and equipment, as well as labor problems, delayed rifle deliveries. The lack of proper equipment, skilled inspectors, and workers adversely impacted Remington’s ability to comply with interchangeability requirements, and many completed French and Russian rifles were rejected as unsuit- able in 1916. Labor strikes added to these delays, resulting in the cancellation of the French “Berthier” and two Russian Mosin-Nagant contracts. |

| Page 24 | 2nd Quarter 2012 |

The Remington Rifle Works in Bridgeport, Connecticut. At the time it was said to be the largest factory in the world, boasting one-million square feet under roof on four floors.

|

Final deliveries of the British and French “rolling block” rifle contracts were completed at the Ilion works under the banner of Remington Union Metallic Cartridge Company. Interestingly, the Imperial Russia Mosin-Nagant rifle deliveries (being made at the Bridgeport Rifle Works) were completed under a different company name. 1.5 million Mosin-Nagant rifles were ordered through three separate contracts. The third and last contract was cancelled shortly after it was signed, and an agreement to modify Imperial Russia’s remaining contracts resulted in modifica- tions to the first contract and the cancellation of the second contract. On March 3, 1917 a new corporation named the “New Remington Rifle Company” was created to manage the massive Russian Mosin-Nagant contract. |

This photograph shows the Remington Mdl 1907-15 “Berthier” rifle in various stages of completion. |

| Page 25 | 2nd Quarter 2012 |

|

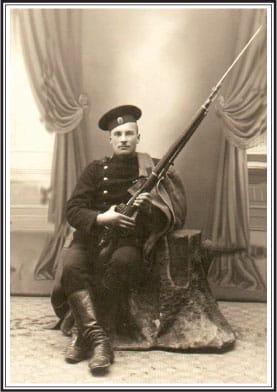

Remington received their largest single order for military rifles during World War I from Russia on January 26, 1915. The contract called for the delivery of one million 7.62x52R Mosin-Nagant Military Rifles and bayonets, at a cost of $30oo each. Remington-made Mosin Nagant Military Rifles are 5-shot, bolt-action weapons which were nearly-identical to their Russian-made counterparts. On July 16, 1915 The Russian Government gave Remington an additional order for 200,000 rifles. And a final order on September 15, 1915 for an additional 300,000 rifles. A total of 1,500,000 rifles in total!

Rem-UMC was given an initial down payment of $7,500,000 from Russia which was used to build the Bridgeport Rifle Works and to purchase machinery and raw materials. Hundreds of thousands of rifles were fabricated in late 1916 and into 1917. |

Unexpectidely, in February 1917, Czar Nicholas II was overthrown, and the Provisional Kerensky Government took over.

On February 25, 1917, the New York Times reported: By November 15, 1917, 513,138 Mosin-Nagant rifles were accepted for delivery to Russia. |

Despite the political turn of events in Russia, Remington continued to fabricate Russian rifles. As late as November 1917, Rem-UMC’s Bridgeport Rifle Works was producing between 4,000 and 4,200 Russian rifles per day, which is an astounding 100,000 rifles per month. Concurrently, the plant was also manufacturing 10,000 Russian and British bayonets per day.

A total of 852,088 Mosin-Nagant rifles manufactured by Remington. Facing a horrific economic loss after Russia defaulted on the balance of the weapons, Rem-UMC was relieved when the U.S. Government purchased most of the remaining, completed rifles, about 78,950 weapons.

| Page 26 | 2nd Quarter 2012 |

|

The Bolshevik revolution in late 1917 effectively halted the Imperial Russian Mosin-Nagant contract with a little over half of the original contract rifles being sent to Russia. Production was resumed under an agreement between the Imperial Russian Embassy and the United States government. This agreement allowed the Imperial Russian embassy in exile to use American credits to purchase additional rifles with which to supply anti- Bolshevik forces in Russia. While the production of Browning machine guns for the United States was being established at Remington’s Bridgeport Rifle Works, Mosin-Nagant production was being phased out. Many of the undelivered Remington Mosin-Nagant rifles were used for U.S. Army training purposes, and some were used to arm the A.E.F. troops which were dispatched to Murmansk, Archangel and Vladivostok in 1918 and 1919. |

|

By the summer of 1918 the Mosin-Nagant produc- tion had ceased. Remington continued filling United States government contracts for rifles, machine guns, signal pistols, Pedersen devices, and bayonets until the end of the war. The Armistice in November 1918 signaled the end of large munitions contracts. After the war Remington sold the Bridgeport Rifle Works and other facilities acquired during the war, returning Remington to its pre-war size.

Details and specifications for Remington’s Allied rifle contracts can be found in the new book by Luke Mercaldo, Adam Firestone and Anthony Vanderlinden – “Allied Rifle Contracts in Americaâ€. The book covers the contracts for all seven rifle models made in the United States for Allied nations during the First World War, including:

|

|

|

Endnote: Prior to the start of the war the merger of the Remington Arms Company and the Union Metallic Cartridge Company resulted in the Remington Arms and Ammunition Company. It was under this name that all eight of Remington’s Allied rifle contracts were signed. This company was reincorporated under Connecticut law as the Remington Arms Union Metallic Cartridge Company, Inc. (Remington-UMC). Remington-UMC assumed all property, rights and obliga- tions of the Remington Arms and Ammunition Company after the incorporation of Remington- UMC. Although Remington-UMC was not the official corporate name prior to 1916, it was used on company publications and firearms since 1911 as a marketing tool. |

| Page 27 | 2nd Quarter 2012 |

| On-line Search/Sort Journal Index |

On-line Journal Articles

|